The French, Dispatched: A DIY French Work Jacket

My thoughts on the workwear staple and how I fared making my own version, no tariffs required.

There’s a long-standing trend in menswear of clothing optimization - finding the best t-shirt, pair of jeans, shirt, suit, etc. that fits perfectly and is durable and stylish and versatile and low maintenance, all for under $20.

I’m being glib (mostly), as I do respect the need to ball on a budget (Five Guys isn’t getting cheaper), but this likely does not exist…okay, the perfect loafer may exist, but otherwise we’re largely out of luck. One thing that comes close is the French worker’s jacket (which inspired the modern chore coat.)

Why This Jacket?

While the French work coat or bleu de travail tends to fall out of favor and then come back into favor in regular intervals, that tends to be a matter of aesthetics of the time. It has many charms, both for people in general and for me in particular:

It’s a utilitarian garment that can be dressed up or down; the button and pocket placement allow it to serve as a more casual blazer alternative.

It’s a low-maintenance garment, durable yet not requiring specialized care (e.g. dry-cleaning, waterproofing or rewaxing).

To a degree, there’s some forgiveness in terms of fit; compared to a blazer or sportcoat it’s less tailored to the body by design and there’s less expectation for it to fit well.

I personally saw the benefit in having something “relatively” normal to wear (since I haven’t commited to dressing like this all the time) in tandem with more interesting pieces OR for days where I wanted utility.

Beyond that, I think the most compelling reason is in its origins.

Historical Context

It started off as a humble garment (along with matching pants), made for French laborers in the mid-19th century as a substitute for aprons and coveralls in uniforms. This wasn’t meant to be a statement piece; in fact its iconic Prussian blue hue was invented by accident.

The charms of the French work jacket were in its utility; traditionally made of moleskin, it served to protect workers from injury and could withstand a lot of wear before needing replacement. If anything, the fading and fraying of the jacket would eventually become a selling point in modern times.

In contemporary times, the work jacket was a symbol of resistance, worn during the May 68 protests by French students in solidarity of workers rights’. Perhaps they took cues from how American students wore jungle jackets to protest the Vietnam War at the same time, or perhaps the sea of blue jackets resembled an ocean of opposition to the French government - it wouldn’t be the first time.

Soon after, Bill Cunningham rose to prominence as a fashion photographer, capturing the stylish commuters of New York in his long-running column On the Street (which serves as the ancestor for similar content online, like Watching New York or Gotham Galleria). He worked for nearly forty years in his distinctive uniform, often sticking out due to his jacket.

I like the unintended parallels between the use of the work jacket in these settings - it was viewed as a utilitarian (or symbolic) garment, typical of an everyday worker, and lacking the pretention of other garments of their respective time. And yet the brilliant Prussian blue injected a dose of whimsy into an otherwise mundane routine (it is, after all, someone’s work uniform), something I consinstently find myself doing when dressing.

The Problem

Bill unknowingly boosted the work jacket’s profile in the public eye, leading to an increase in demand and reproductions of the classic jacket, even as brands like Le Labourer and Le Mont St Michel continued production in France. This wasn’t a problem for Bill, who bought them 30 at a time, but for me:

I disliked the reproductions, either for being too short and too slim or else made with different material (especially with my lack of budget).

Vintage jackets were hard to come by (mainly because I was picky); jackets from France were expensive, jackets from elsewhere were either differently colored or cut, and shipping was a mixed bag.

I was very close to purchasing one off Etsy and waiting a month, but fell backwards into a different option - making one myself.

The Process

As is custom on a Sunday afternoon, I wound up buying a bunch of stuff from a local vintage reseller, including a Dickies medical lab coat:

With the notched lapel and three pockets I immediately figured I could dye the jacket blue to make a variation of a bleu de travail. The lab coat was a true-to-size Medium, with a little extra length in the sleeve and body; from my last attempt at dyeing stuff I knew shrinkage would occur and felt I had enough fabric to make up for it (things said before disaster).

My target color was indigo, with the thinking that sun damage would take it to a more blue-lavender color than a flat powder or denim blue. As with the last time I used Rit, had two options:

Indigo dye, which seemed more purple than blue (as in nature), and

Indigo formula, which was good on paper, but in practice made for a very muted, very dark color.

I reconfigured the indigo formula slightly, replacing the graphite gray with royal blue, which yielded 2 cups of composite dye, lighter and more saturated than previously attempted. Given that I shared laundry facilities with other people, I used a giant stockpot for the dyeing process, using roughly 3 gallons of water, along with 1 cup of salt to further enhance the color and 1 tablespoon of dish liquid to promote even dyeing.

Dyeing process:

Brought water to near boiling (I temped it at 200F being overly cautious, but could’ve just used visual indicators) and dampened the jacket.

Added dye mixture to hot water bath, stirring until incorporated, then dropped the temp to a simmer.

Added the dampened jacket, stirring often for 15 minutes, then every so often until submerged for an hour.

Placed a collander inside a larger bowl, then dumped the jacket and dye water into the nested bowls while I cleaned; I figured this would enhance the final color of the jacket. Rinsed out the excess dye afterwards.

Washed alone in warm water wth Dr. Bronners baby soap (mild, fragrance free, more gentle on clothes). Dried on no-heat for 90 minutes total.

The results:

I was pleased with the even distribution of color, even though there was an underlayer of white visible in the body of the jacket and seams. Because the jacket was a poly-cotton blend, the dye didn’t fully take to the polyester (hence why the buttons remained white), but it gave the effect of weathering which I deemed a positive. There was only one negative - shrinkage:

Admittedly, the button down shirt pictured is oversized, but even accounting for that, the jacket shrunk from a Medium to a Small (almost XS), likely due to the carry over heat shrinking the fibers while I was cleaning. My options were limited - do I donate the jacket? do I try to detach and reattach the sleeves? Neither sounded like a good choice.

Instead, I took a third option in attempting to block the jacket. By soaking the jacket in hot water and conditioner, the jacket fibers in theory would be loosened enough so that I could stretch the sleeves and body. While blocking is usually done with wool items, I figured that the cotton component would act similarly and yield enough extra length to make the jacket wearable.

My steps to blocking:

Filled a basin with hot water and 1 tbsp conditioner (my conditioner of choice is SheaMoisture; this does have implications overall)

Submerged the jacket, then let soak for half an hour, turning periodically.

Let the jacket drip dry, then rolled in a clean towel to soak up the remaining liquid.

Stretched out the jacket on a giant piece of cardboard. I used a potted plan and sauce jars initialy to weigh down the ends of the sleeves and collar, and then used straight pins to fasten the seams.

Turned my ceiling fan on high and let air dry overnight.

Released the pins the next morning, after more than 12 hours.

Interestingly, the color of the jacket appeared more vibrant, which I suspect came from the conditioner (truth in advertising I suppose), but it also seemed flat. In response, I found some house paint to splatter on the jacket intermittently and let dry through the day.

The Results

The color of the jacket turned out great, but the blocking didn’t work as intended. While the ingredients of the conditioner yielded a much richer color (and coconut smell to the jacket), they weren’t strong enough to loosen the cotton fibers, especially with the carry over dyeing. The sleeve barely grazed the top of my wrist, level with the button up worn underneath, so in the moment I turned up both in an effort to be insouciant (it didn’t work).

In addition to its size, the jacket proven to be very thin, made with a single layer of poly-cotton fabric. In a vacuum this would be fine, but because of the shrinkage I couldn’t effectively layer underneath it vs a traditional work jacket. I though the jacket could be worn as a solely warm-weather layer, and then later as a midlayer, but these seemed like reaches to justify my earlier actions, similar to how I’d jump through hoops to salvage a bad buy.

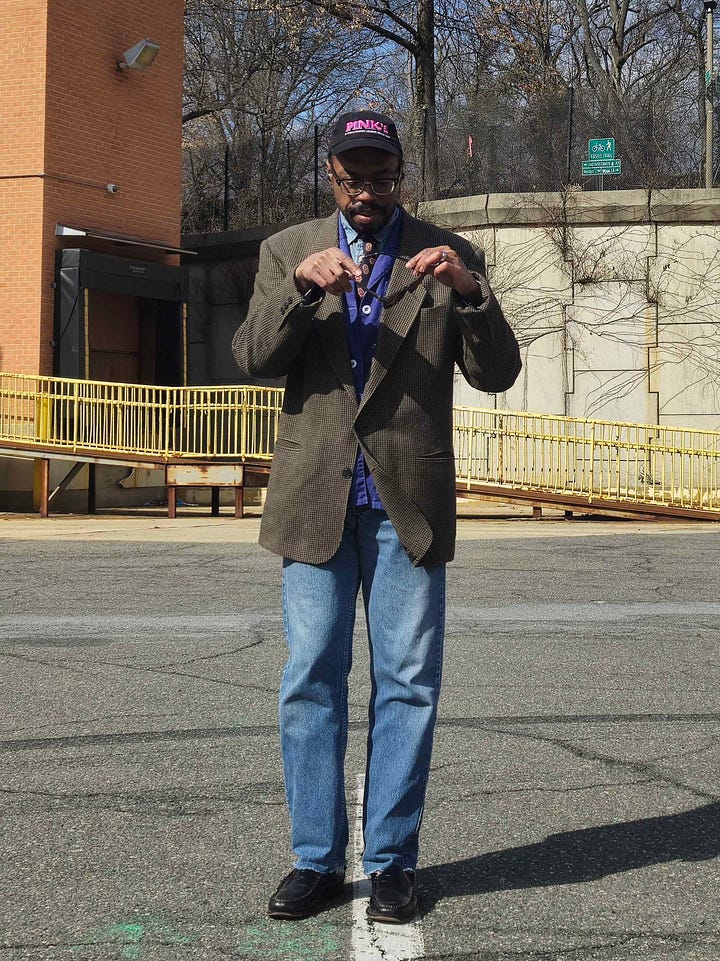

I wasn’t really feeling these fits either. The first felt like an obvious attempt to throw stuff on in an attempt to look uncaring, but the jacket clashed and in hindsight there’s no real reason to wear a second undersized midlayer over a button down when I could just wear something else instead. The second was better - the indigo works as a nice buffer to the denim components - but I was disappointed that the best use scenario was covering 90% of the jacket.

Conclusion

Given the lengthy cold winter, I wore more functional clothing and had a chance to reflect on what I wanted in doing this process. While my intended goal was to have a functional “normal” jacket, I already had blazers, sportcoats, and other outerwear; I had no functional need to own this.

So then what was the point? Ultimately it was to create something organically, being able to see something discarded, visualize how it could be turned into something useful, and acting upon it. Maybe there’s a little bit of martyrdom attached to that thinking, but I do think my desire for sustainable living and general curiosity intersected here.

Given my usual tendency is to have some sort of (great) tangible output, it was a nice change to say “that didn’t work out.” While the actual jacket wasn’t ideal, working out the processes, troubleshooting, and recognizing why things didn’t work out, is a net positive for future efforts.

…is what I would’ve said three weeks ago.

The Process, Revised

Months after dyeing, I was at Goodwill looking for a striped button down shirt, and found another white Dickies lab coat, only this one was a size 2XL. I still had some blue dye at home and reasoned that, with the rate of shrinkage on the first jacket, I’d end up with a somewhat oversized version of a French work jacket this time. Given the low stakes, I figured I’d try again.

Unlike the past instance, my measurements were less precise - I had 1.5 bottles of dye to use and just used all of it up. Rather than going through the mental math, I figured there wasn’t much difference in weight between the two jackets and used the same amount of water, salt and dish liquid for dyeing.

There were two other changes in this process worth noting:

After mixing the dye and the near boiling water, I left the heat on the dye liquid as I submerged the jacket. This was an accident, and after about ten minutes of stirring, I realized my mistake, turning down the heat to a simmer for another twenty minutes.

Immediately the dyeing process, I used a dye fixative - while it was counterintuitive to the idea of a worn looking jacket, I wanted to avoid potential color bleeding when washing. I followed the directions on the package and then rinsed out the excess dye.

The washing and drying process remained the same, and after the jacket was cooled off I was able to compare the two jackets.

As before, the dye dispersed evenly, perhaps even moreso than the first attempt due to the extended stint in hot water and the dye fixative. I suspect the heat is also what enabled the dye to work on the buttons, turning them from white to baby blue - I had not expected this change but was pleasantly surprised. The one negative from the excess heat is some extra puckering at the seams, but that’s mainly noticeable at the lapel:

The Results, Updated

Seeing the jacket in natural lighting puts things into better context - the color isn’t as vibrant as the initial jacket but is still very blue, and the wrinkling gives the worn effect that I initially hoped for (though I eventually ironed it). Though the jacket shrunk slightly, it still fastens, and is great length/width in the body and sleeves for layering, which I will call a success.

While I was been content with having a valuable lesson in knowing my limits and needs, I’m glad things worked out the way they did. As it stands, I now have a test dummy of a jacket to do things to in learning, plus a tangible display of my efforts.

Thanks for reading - any feedback is appreciated. Follow me on Instagram to see more short-form content, and subscribe through the link below to be updated when new posts go live.